Compressed Air Filter Applications

Compressed Air Filter Applications

The need for filtering compressed air to make it usable is vast. Compressed air is not usable as a utility directly from the compressor source. It needs to be prepared and cleaned by a compressed air filter or dryer to various levels of cleanliness, depending on the task at hand. Spray painting, blasting, pneumatic tool preservation, surface preparation, pneumatic controller protection, and worker safety are just a few of the needs for clean, compressed air.

In today’s workplace, compressed air is the other utility that must be prepared to a level of cleanliness necessary for the task at hand. It seems to be the utility that is most often used and normally given the least attention or thought.

Often compressed air is overlooked and misunderstood. The use of compressed air is an ever increasing demand. That said, compressing air and sending it downstream through a system of plumbed lines is not a usable commodity. When we compress the ambient air, we squeeze the water moisture that is held in the air, into the tank where it becomes liquid. This liquid mixes with the oil used to lubricate the compressor. Then this oil/water moisture travels downstream and picks up contamination from the lines and hoses, which is all then deposited into the tool being used or the object subjected to the compressed air stream. All of these issues are not acceptable.

The need for filtering compressed air to make it usable is vast. Compressed air is not usable as a utility directly from the compressor source. It needs to be prepared and cleaned by a compressed air filter or dryer to various levels of cleanliness, depending on the task at hand. Spray painting, blasting, pneumatic tool preservation, surface preparation, pneumatic controller protection, and worker safety are just a few of the needs for clean, compressed air.

In today’s workplace, compressed air is the other utility that must be prepared to a level of cleanliness necessary for the task at hand. It seems to be the utility that is most often used and normally given the least attention or thought.

Often compressed air is overlooked and misunderstood. The use of compressed air is an ever increasing demand. That said, compressing air and sending it downstream through a system of plumbed lines is not a usable commodity. When we compress the ambient air, we squeeze the water moisture that is held in the air, into the tank where it becomes liquid. This liquid mixes with the oil used to lubricate the compressor. Then this oil/water moisture travels downstream and picks up contamination from the lines and hoses, which is all then deposited into the tool being used or the object subjected to the compressed air stream. All of these issues are not acceptable.

Quality Products

Our unique compressed air filters provide clean compressed air by utilizing media-based filter design

Made In The U.S.A

All of our quality compressed air filters products are designed and produced in our facilities right here in the U.S.A

Made In The U.S.A

As an industry leader Walmec North America provides the widest ranges of compressed air filtration products.

Did You Know?

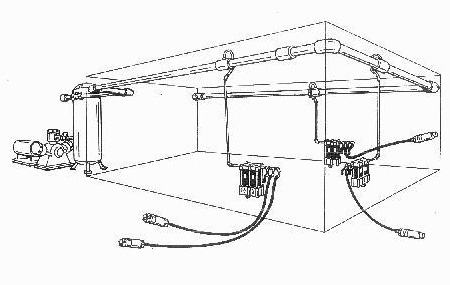

Even with a properly installed refrigerated air dryer located at or near the air compressor site, the fact that your plumbing is exposed to the changes in temperature will allow moisture to reappear along this route.

Even worse is when the plumbing is allowed to sag or have low spots to drop around a structure or object. This low spot will, over time fill with moisture, and perhaps compressor oils, that at some point will move downstream into your pneumatic tool, or spray paint application, all at one time. The best advice to make sure this does not happen is to install a properly sized compressed air filter at the point of use.

©2020 Walmec North America P.O. Box 328 ■ Mazeppa, Minnesota 55956 866-764-8377 ■ 507-843-4703 Fax: 507-843-4953

Powered By Carbon Behavioral Targeting